Xiamen Seebest Wire & Cable Co., Ltd.

Production Process

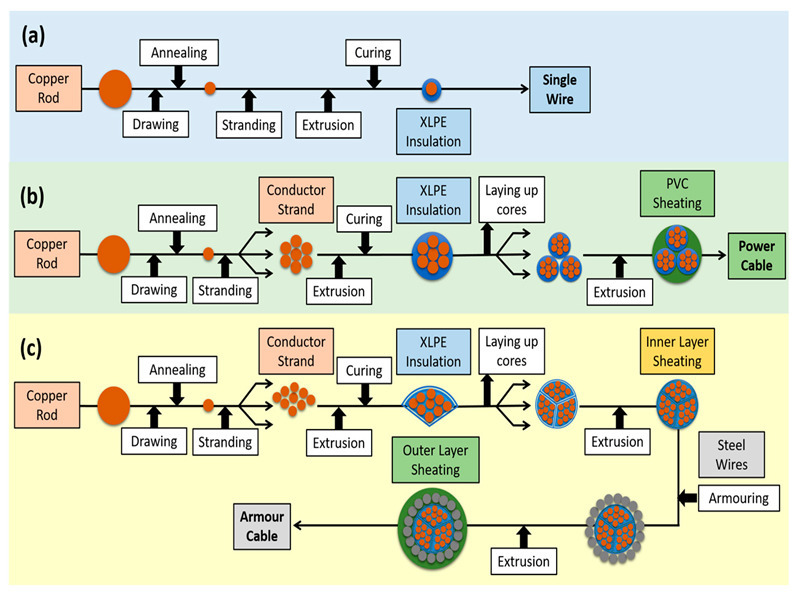

Production Process and Equipment for Products

Since the establishment of the company,"Seebest Cable" has purchased a lot of advanced production equipments, as well as many experienced staff, developed a practical and standard compliant production process, to ensure that all products can be passed the testing of domestic or international standards, and met to customer requirements.

For wire and cables, each production process is very important, but "Seebest Cable" would like to remind that there are some key production processes, because they can directly affect the quality of products. These processes include but are not limited to Copper Wire Drawing (large drawing, medium drawing and small drawing), Copper Stranding (single stranding, pair stranding, twin stranding, concentric stranding, bundle stranding, frame stranding, cage stranding, coiling, etc.), Plastic Extrusion (insulation and sheath materials).

The production process of "Seebest Cable" as follows:

The production equipment of "Seebest Cable" as follows:

Tips:

"Xiamen Seebest Wire & Cable Co., Ltd", was founded in 2009, and is located at No. 372, Huanzhu Road, Jimei District, Xiamen City, Fujian Province, China.

"Seebest Cable" is a manufacturer specializing in the Research, Development, Production, Sales and Service of wire and cables for customers at home and abroad.

"Seebest Cable" always adhered to the business philosophy of "Honesty and Trustworthiness, People-Oriented, Quality First, and Win-Win Cooperation", providing the Reasonable Prices, Value-added Products, Quick Delivery, Professional Technology, and Warm Services to the customers.

After years of rapid development, the company already won the trust and support from the customers at home and abroad, and "Seebest" has become a well-known brand in the industry.

Contact Us

+86 18959293828

+86 18959293828

No. 372, Huanzhu Road, Jimei District, Xiamen City, Fujian Province, China.